On a recent trip to England, this little spindle moulder caught my eye:

I had been looking for a cheap shaper I could steal the fence from. I have a few European machines that are missing the split style fences that mount into the dovetailed slots on the table. As an example, this Pierre Benite shaper is just about perfect, but lacks a fence:

I decided to take a closer look at the machine and realized that it had a number of features that could be quite useful.

First, it has this add-on sliding table:

It only has about a 24″ stroke, but still very useful with this heavy vise/clamp:

Then it has an overarm bearing support for a long spindle:

It has a bunch of spare parts ( spare spindle, cutters, etc)

I might have bought it just to get the handy little Spanner bracket:

This shaper is belt driven. The design is more like the Wadkin EP or the old Onsrud where there are v belt pulleys at the lower end of the spindle and the spindle moves through the lower bearing block:

The original contactors and switchgear have been replaced with a modern mag starter and placed on the outside of the machine. The original cover plate is still there for the push buttons, but the innards have been removed.

It’s also equipped with a hand brake and spindle lock:

Getting a single machine moved from The North of England to Somerset New Jersey is a somewhat costly proposition. It’d have to be a pretty nice machine to warrant the expense and trouble. This is especially true considering the abundance of very good American made shapers that are available these days. It would have to be a pretty special machine. Right?

Well, it does have one feature that puts it over the top:

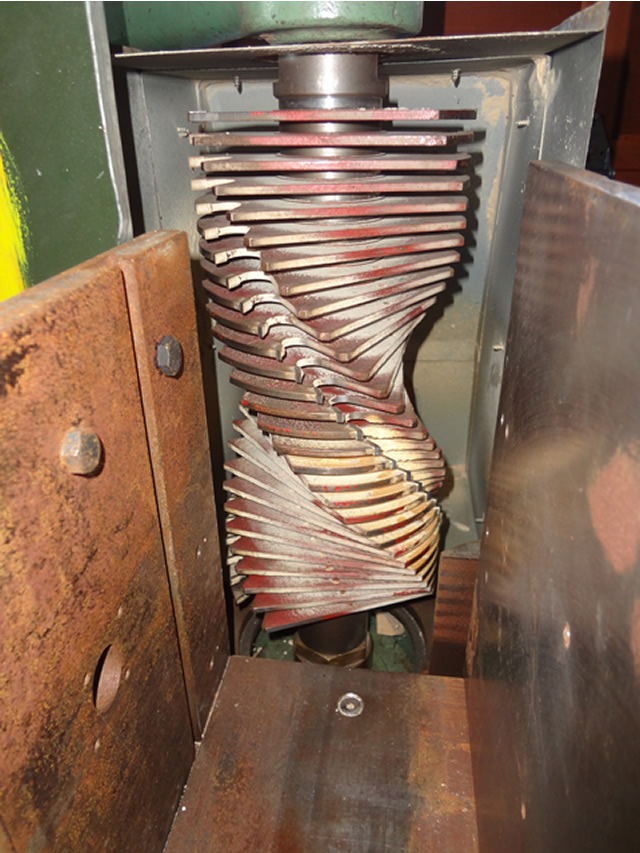

That would be 16 inches of box joint (corner lock) cutters. Here’s a closer shot of the stack:

I have not disassembled this spindle yet, but these are all carbide tipped with spacers between them. I’ve seen a few shapers with a small stack of dado cutters setup for this operation, but never anything like this. Between the spindle setup and the rolling table, this machine is every bit as fit for this purpose as a Morgan box cutter. Since all of those machines now reside in a low, dark, non-descript warehouse in south central Pennsylvania or an old airplane hanger in central Vermont, this is the next best option. For my purposes, this is better since I have a shaper a tenoner and a box joint cutter in one machine. It was a whole lot less expensive too. Given the propensity of some folks to spend six thousand dollars (or more) on a single box joint machine, this was a bargain at 180 quid.

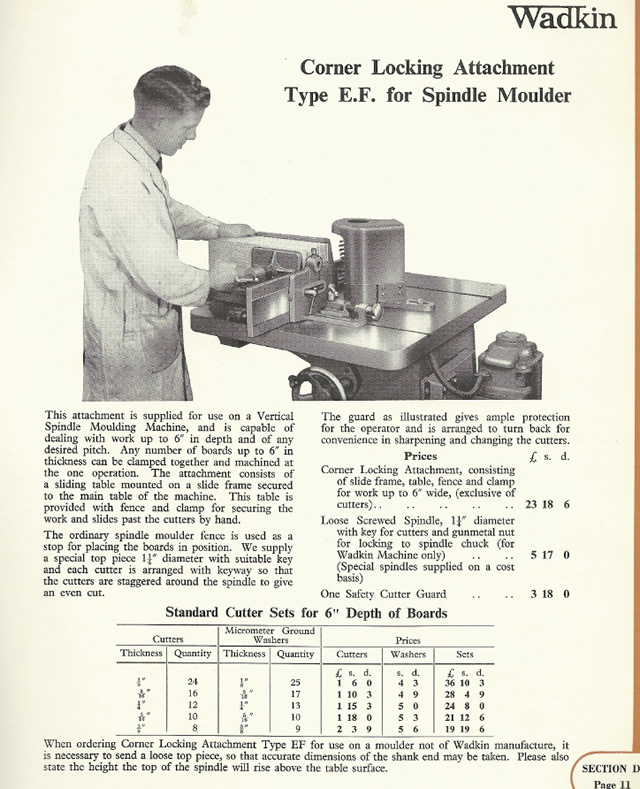

Addendum 05/04/14: I was browsing my Wadkin tool catalogue (1952) this morning and realized that the fence, rolling table and cutters are all an add-on from Wadkin. It’s designated as the “Corner Locking Attachment Type E.F.” What’s interesting is that the kit on my shaper is nearly three times as high as the spec shown in the catalogue. Most likely a piece of custom work.

That is a very nice find Arthur. I’m surprised I never sniffed it out seen as it was from the north. I’m even more surprised Sion Dovey did not find it he loves Sagar. I got a nice PK recently, it has the table extension plus an oversized slider.

Mark,

It’s good to hear from you. I was also surprised by the low price. It was in an on-line auction, with not so great pictures, but if you really looked, you could see the spares and second set of cutters. This prompted me to go have a look at it. Even more surprising was the fact that it was at a machinery dealer. Congratulations on the PK. Were the fence, graduated scale and stops on the rolling table extension? If so, I’d enjoy seeing some photos. I picked up another English shaper this past week. I’ll be posting it shortly.

Cheers,

-Arthur